- Low initial cost

- Simple design with no moving parts

- Requires less maintenance

- Can be operated continuously

- No blower requirement

- Simultaneous gas absorption and particulate scrubbing

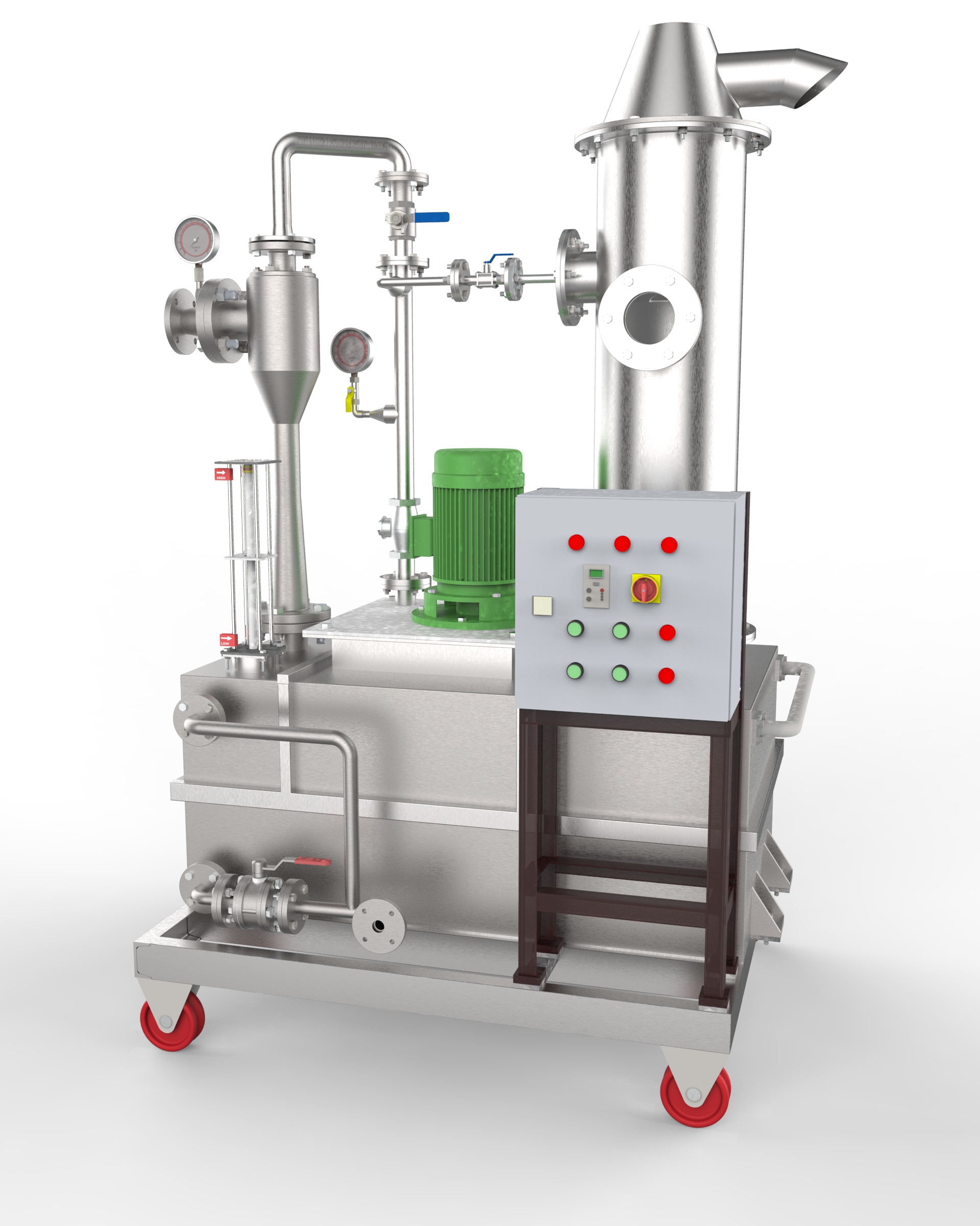

The Jet ejector venturi utilizes a large scrubbing liquid volume introduced through a special high pressure nozzle to aspirate the pollutant laden gas into the chamber in a concurrent flow pattern.

As the gas enters the throat section, formed liquid sheets and droplets are sheared and break up into much smaller sizes due to the high relative velocity difference between the gas and liquid.

These extremely small droplets create a tremendous amount of surface area for gas absorption and impaction collection of particulate to occur.

In addition, the velocity of the liquid spray creates a negative pressure which pulls gas into the Scrubber.

Due to the even distribution and large volume of liquid throughout the throat cross section gases can be scrubbed even at extremely reduced rates with no appreciable decrease in removal efficiency.

The gas with pollutant containing liquid droplets then proceeds out of the throat into the diffuser section where further scrubbing action occurs.

Droplets are removed from the cleaned gas in the entrainment separator before the cleaned liquid free gas exits the system.

The liquid with contaminants drains through the outlet.

Their advantage is the ability to handle high concentrations of gases such as Chlorine or other water soluble gases. In many applications, the Jet Venturi can be used without any additional fan. Jet Venturi scrubbers use the energy from the liquid sprayed into the Venturi to create a pull on the gas drawing it into the scrubber. The gas and liquid are then mixed in both the spray section and in the high velocity Venturi throat.