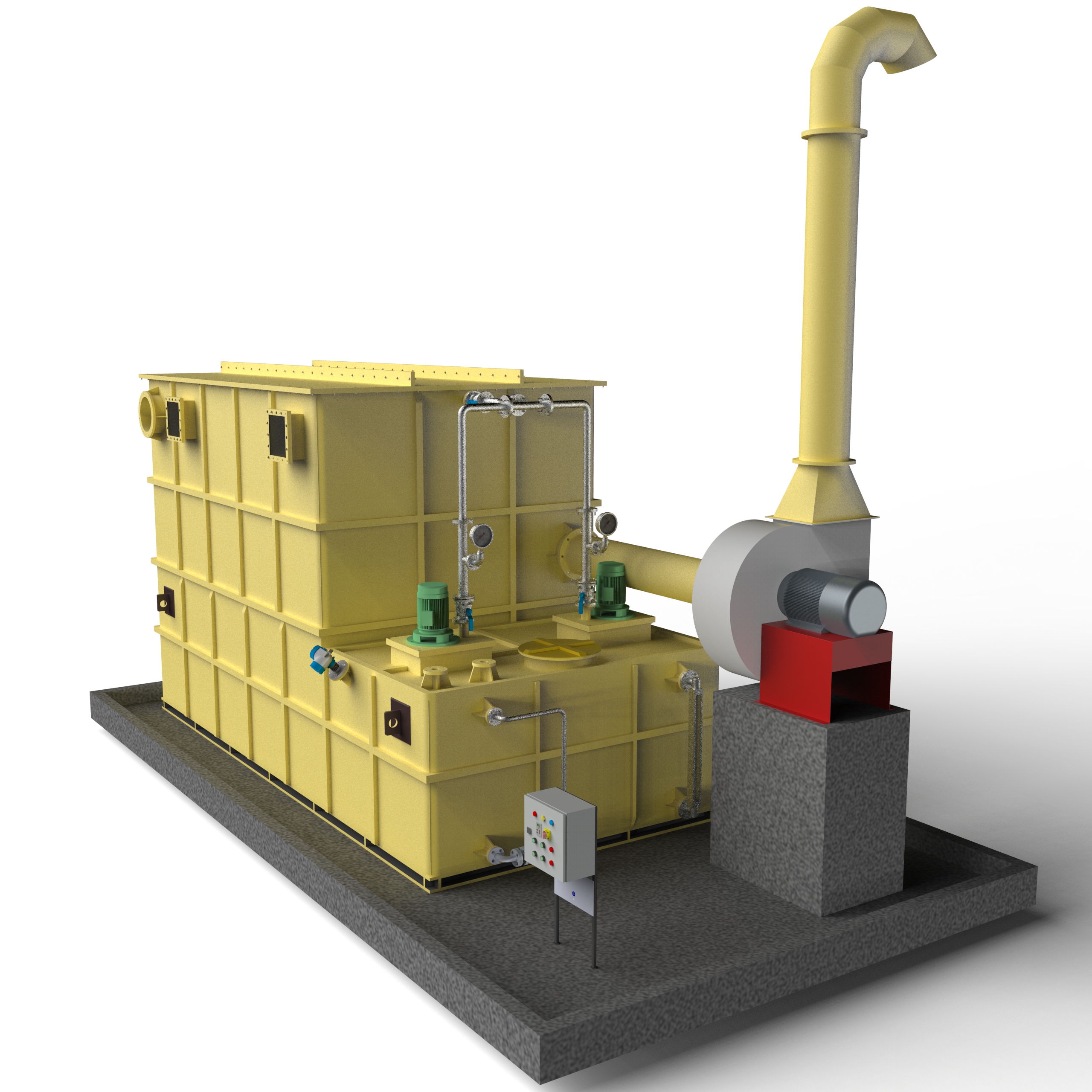

The emergency chlorine vapor scrubbing system is a three-stage chemical absorption system consisting of a horizontal cross flow spray system followed by two horizontal cross flow packed bed sections.

An induced draft fan pulls vapors through the scrubber, where intimate contact with a recirculating caustic solution results in the complete absorption and removal of chlorine or sulfur dioxide vapors.

A high efficiency mist eliminator is located in the gas stream, prior to exhaust, to remove any residual caustic solution. A chlorine detector or manual remote start switch activates the system in two steps.

The caustic pump is activated first to permit proper wetting of packing in the scrubber stages before starting the exhaust fan, with a 0 to 5 second adjustable time delay. The time delay is typically set for 3 to 5 seconds. This feature allows the scrubber to be ready prior to passing any chlorine laden gases through it.

The exhaust fan is placed downstream of the scrubber. This feature allows the complete system to be under negative pressure until the gases are completely scrubbed. The absorber is placed on top of a caustic storage tank, which is an integral part of the system.

Scrubbing liquid is supplied to the motive inlet under pressure. As a result of the large drop in liquid pressure across the nozzle, a high velocity liquid spray exits the nozzle. This atomized liquid provides surface area for transfer of mass from the gas to the liquid phase and allows for capture of particulates from the gas phase due to impaction. In addition, the velocity of the liquid spray creates a negative pressure which pulls gas into the Chlorine Scrubbers.

The chlorine is neutralized using caustic solution. The unit is designed based on risk analysis study to prevent release of chlorine directly into atmosphere.

The scenario considered are:

The chlorine concentration should be monitored continuously near the toner and should be ensured that concentration is less than 3 ppm

Fusible plug worst case in the 900 kg toner

Considering safety factor, suction air flow required is 3000 CFM to evacuate entire chlorine gas from leakage area.

For 50 kg toner, considering safety factor, suction air flow required is 250 CFM to evacuate entire chlorine gas from leakage area.

In the scrubber system, Chlorine is neutralized by using sodium hydroxide and gives by product of sodium hypochlorite and sodium chloride.

Cl2 + 2 NaOH --> NaOCl + NaCl + H2O

Sodium hydroxide solutions are the most commonly used for typical scrubbing applications. However, the other chemicals listed above have been successfully used in many applications where they may be readily available, less expensive or satisfy the specific application.

Drizgas Tech is one of leading manufacturer of Emergency chlorine scrubber in India. We provide highly efficient, top-quality scrubber system built around your precise requirements. Contact us with your process information so we can begin discussing the type of new equipment that best fits your situation.